Hello, welcome to Shenzhen Taigang Machinery Co., Ltd.!

Business:0769-81698040 13509666635 Technical Support:13509650331

中文

English

Ingersoll Rand CENTAC centrifugal oil-free air compressor

Interview

To meet the needs of industrial development, since 1911, the United States has been engaged in Ingersoll Rand centrifugal air compressor design and production work, and always maintained a leading position in the world. With years of experience in production and design capabilities and finally in 1968 built the first CENTAC brand centrifugal air compressor production line. Since that date, more than 2,000 units CENTAC unit operating in the world in various fields of industry

Automotive Manufacturing

Number of units already installed more than 400 units

Automobile manufacturers to use than the number CENTAC centrifugal compressor with other brands of compressors to be more

Including the use of assembly plants and parts manufacturing plant

Textile / Fiber Industry

100% oil-free air to ensure continuity of production

The compressor has been installed more than 1,000 units

Including the use of air-jet looms, air spinning, winding yarn paddle a variety of uses

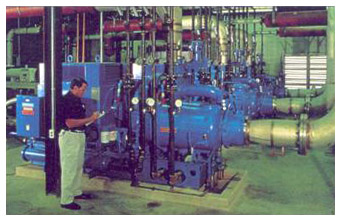

Steel / air separation

Widely used in iron and steel, air separation industry in the domestic market share leader

Available than air, compressed nitrogen

Can provide high pressure air, to meet customer demand in this sector

Provides a more flexible control solutions to meet with customers existing DCS and other plant control systems

Energy efficient.

Chemicals / refining industry

Dedicated set design, fully meet API-672's operating performance and reliability

Heat exchanger can be chosen according to your requirements

There are a variety of structural materials chosen to accommodate different working environments

Power Industry

Ingersoll Rand is a centrifugal compressor boiler soot blowing technology pioneer, has 25 years of experience

Can provide a full range of types of blowing air compressor

With 6psig (42bar (g) to (42bar (g)) of the pressure range. Applications include boiler soot blowing, instrument and utility air, ash conveyor, gas desulfurization

Control system is designed so that the cyclical changes in the volume of air able to respond quickly

It can be widely used in other industrial fields, such as

- Coal

- Glass Manufacturing

- Artificial snow and

- Electronics

- Food and Beverage

- Drugs

PET blow

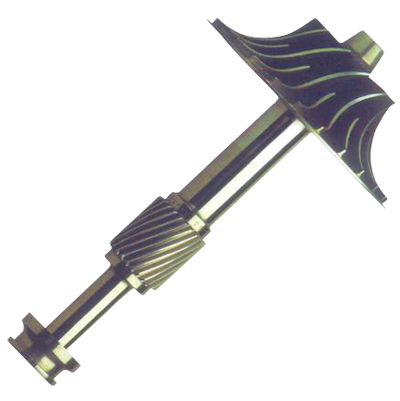

Well-rotor

A typical single axle wheel design to shorten the length of the rotor, to minimize the weight of the boom, so that the rotor has the best combination of stability. Impeller and diffuser gap between the work from the air or water temperature change

Semi-open three-dimensional flow backward curved impeller (originally developed by the Rand Corporation) and the unit has the best control, while allowing maximum operating range

CENTAC impeller made of special high-pressure casting cast stainless steel by forming a dense, high strength and corrosion resistance characteristics

Thrust ring effective aerodynamic thrust disperse transmitted to the chassis, so that the main gear does not bear the load, the maximum extent possible to extend the life of the gear

Unique arc triangle fraction ensures thrust ring, impeller and pinion self-locking connection between the firm and make disassembly is very simple. This arc triangle connection also increased the contact area, compared with keys or hot sets of connections, longer life

Superior mechanical transmission

CENTAC rotor assembly optimize efficiency, ensuring reliability, and simplify maintenance

Stable pinion stub shaft so that it can adopt a simple structure fixed three-tile set of simple bearings. The bearing has no moving parts, no annual maintenance

Bearing all the conventional low-pressure lubricating oil system, lubrication, in order to achieve an effective gear lubrication and film stability. Oil from the installation on the main oil pump shaft and is equipped with a computer-assisted pump

Axial thrust is small, one-way, and can be predicted to minimize energy consumption. Minor thrust side of each gear by a fluid dynamic pressure bearing absorption

Standard radial and axial thrust bearing no moving parts. This simple structure can be passed-shaft bearing on the operation of effective monitoring, and thus eliminates the need for regular maintenance time and costs

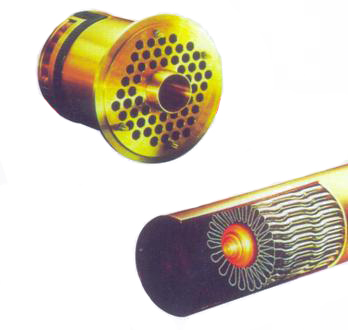

Efficient heat

CENTAC unit, the air in the tubes and water management, air cooler has the following main features

Contact surface with water --- gas - is out of reach double tube cooler, so that the cooling effect is better, lower temperature, and after the scaling caused by deterioration of machines running less likely smaller. thus reducing the flow of cooling water cooler and maintenance workload.

The design avoids the intercooler piping hot out of the air compressor connection problems. In CENTAC design of exposed pipes, avoiding the use of expensive pipeline expansion joints. Water management, but also plays the role of air noise isolation

CENTAC air cooler may recoil at run time, or on-site cleaning. Both methods minimizes the downtime required for cleaning cooler

Overall assembly design

CENTAC the overall assembly design has many advantages, but the main advantage is simple structure. Completely assembled CENTAC compressor and piping on the main components in the factory had installed, which makes on-site installation work is very simple. And tight beat structure also eliminates a lot of your time and money

Advanced lubricant system

Low oil pressure (25PSig)

SAE standard O-ring to ensure no oil leak runtime

Main oil pump driven by the spindle

Oil heater

Built-in air cooler

Compact, high-efficiency cooling

No external piping, easy to install

Reduce the expansion joint

No exposed air ducts

Built-in air line reduces the noise level

Completely assembled compact design, small footprint

Reducing the pressure loss

Some models are equipped with water dispenser

Simplified bearing design

Fluid dynamic pressure (film) radial bearing

Full echoed reverse thrust hydrodynamic bearing

Radial bearings and thrust bearings are pre-installed in the respective bearing housing

Simple rotor structure

Uniaxial single impeller design

Better efficiency

Minimum bearing load

Low vibration

Each is equipped with a vibration sensor for condition-based maintenance

Assembly structure designed according to your needs, including

Control Systems

Lube oil system

Heat exchange means

Bearings

Other

Vertical section housing

Structural integrity, easy disassembly of all parts

Just set the gap

Rotor gap adjustment can be carried out outside the machine (without opening the case)

No routine annual maintenance

Non-contact air / oil seal

Full floating graphite ring

In any operating conditions can ensure no oil, so that the possibility of air leakage is reduced to a minimum

Computer controller designed for you

Ingersoll-Rand Company is the world's first computer used air compressor manufacturers, CENTAC microcomputer controller is an outstanding control system, allowing you full control of the machine. The heart of the system is an advanced computer processors can be self-regulating, it can be fully integrated to the compressor body, motors, switchgear and auxiliary equipment control

User-friendly user interface

12 simple button control panel

Large screen display more data to facilitate monitoring the operational status of the unit

Chart shows the unit operating parameters, alarm and shutdown settings

Set parameters via touch buttons

Languages and units of measurement showed that Chinese show

Self-diagnosis function

224 alarm, shut down the operating time records

Event Logging simplifies troubleshooting and analysis

Failure detection logic controller

Surge absorption technology reduces the system pressure fluctuations, improved operational stability

Reliable operating performance

When all of a sudden power failure automatic memory operating parameters

Automatically adjust when power is restored to operational status before power

System management functions

Old models of centrifugal air compressors (even non-IR crew) can also be easily upgraded and incorporated into an automatic control system

Flexible control

- Standard automatic dual-saving control mode

- Standard constant voltage control mode

Powerful communication features

Using the optional Universal Communication Module (UCM)

Signal can be received in the whole plant control system

UCM module supports MODBUS and AIIEN-BRADIEYDF-1 communication protocol

UCM module also receives via modem modem command, communication

Existing energy management system software to help save more energy costs

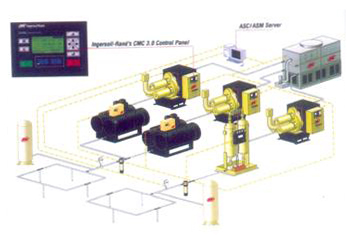

ASC / ASM centralized compressed air control system

To control the compressed air system, including centrifugal. Screw, reciprocating compressors, and all auxiliary systems, such as dryers, pumps, cooling towers, piping and valves of the measuring point.

Energy management can be optimized through load distribution function, automatic monitoring, control and reduce the waste of energy of compressed air

Control up to 32 air compressors

Can be multi-pressure system control

Using a graphical interface for display

Sequence control function

Multi-language system (including Chinese)

Superior communication capabilities, through

Single or multiple PC

LAN Local Area Network

Internet

When you need service, our support will be on your side

CENTAC worldwide service

When our air compressor shipped to your facility, our responsibility is even more significant. As a global company, our mission is to reduce your compressor in the whole process of cost consumption. We will provide you with the most completive and most efficient service and support, continue to carry out product quality and improved aerodynamic research and engineering technology to improve the ability to achieve the purpose of reducing the cost of compressed air

User Support

On the response of your needs

Global networking services 24 hours

The latest technology

User record

Ingersoll Rand Ingersoll Rand's original spare parts provided by the Quality Assurance

User Training

Regional Service

Quickly and effectively to serve you

Worldwide reputation for superior service and

In the world has more than 150 offices

Factory-trained service personnel

Compressed air system energy accounting

Compressor maintenance contracts

Local spare parts warehouse

Local Customer Training Center

CENTAC continuous improvement

Through the use of controlled, qigong and mechanical reliability of the latest technology to constantly improve your device, saving you the cost of

Reduce energy consumption

Lower operating costs

Reduce maintenance costs

Improve processes

Engineering and technical services

The compressor to reduce operating costs during the life

CENTAC Diagnostic Services (CDS)

CENTAC software, including energy management systems, etc.

Lubricants

Controller

Lubricants and air quality analysis

Refurbished units

Copy product links

Copy product links

Long by picture save/share

Long by picture save/share