Hello, welcome to Shenzhen Taigang Machinery Co., Ltd.!

Business:0769-81698040 13509666635 Technical Support:13509650331

中文

English

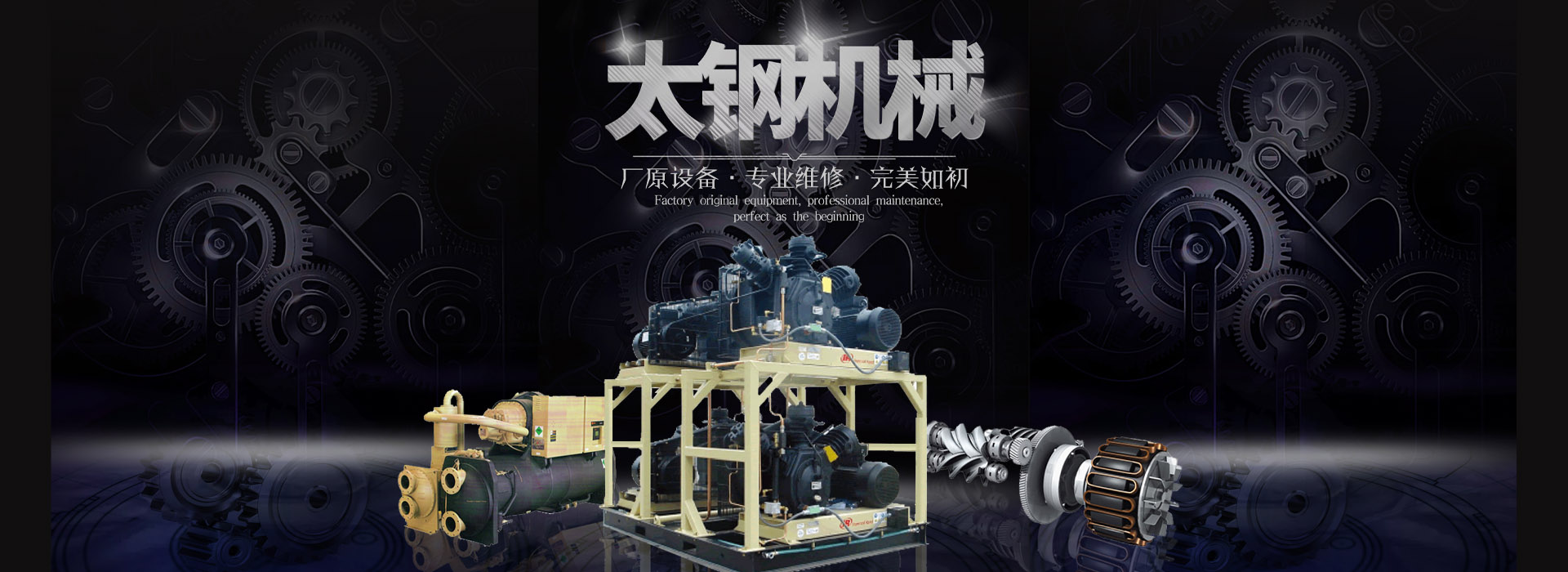

HP series piston air compressor

Interview

Efficient and reliable HP Series Air Compressor - specially designed for the high-pressure air system

75 years, Ingersoll Rand HP series piston air compressor with its excellent quality of leadership to the compressor market.

The air-cooled , multi-stage compression, splash lubricated air compressor motor power range of 3-15 horsepower , the design pressure range is 3. 0OMP to 7. 0OMPa.

HP Series high pressure air compressor design is simple, high reliability and easy maintenance. Heavy duty design ensures optimum performance of the unit and the lowest maintenance costs. When you need a low running cost , but superior performance, high-pressure air system, air compressor Ingersoll Rand's HP Series is your best choice.

Scope of supply units

- Get heavy cast iron cylinder

- The oil level sight glass

- Inter-stage safety valve and pressure gauge

- Non-return valve and the exhaust valve

- Interstage outfall drain valve is installed manually

- Efficient TEFC motor , IP54, 1.15 service factor

- Heavy steel base

- Belt guard

-V -belt drive

- High pressure switch ( sent at random )

- Magnetic Starter ( sent at random )

-15HP and below, direct start

- Factory perfusion XL740HT synthetic lubricants

Options

- Low oil level switch

- Automatic condensate drain valve

- The amount of delta starter

High pressure compressors are widely used in various industrial fields, high-pressure compressed air has many applications, it not only can be used in the military, but also for the commercial and recreational diving, fire providing for compressed breathing air, and, in the automotive and air conditioning industry, but also can be used as a pressure test medium.

Another important application of high-pressure compressor is a single-step or two-step method of blow molding process provides compressed air, Ingersoll Rand HP15-30P high pressure air compressor is designed to meet the needs of manufacturing industries look design.

Scope of supply units

- Heavy duty cast iron steam

- The oil level sight glass

- Inter-stage safety valve and pressure gauge

- Non-return valve and the exhaust valve

- Interstage outfall drain valve is installed manually

- Efficient TEFC motor, IP54, 1.15 service factor

- High temperature alarm switch

- Intake valve to achieve constant speed control unit

- Heavy steel base

- Belt guard

-V-belt drive

- High pressure switch (sent at random)

- Direct start magnetic starter (sent at random)

- Factory perfusion XL740HT synthetic lubricants

Options

- Low oil level switch

- Automatic condensate drain valve

Copy product links

Copy product links

Long by picture save/share

Long by picture save/share