Hello, welcome to Shenzhen Taigang Machinery Co., Ltd.!

Business:0769-81698040 13509666635 Technical Support:13509650331

中文

English

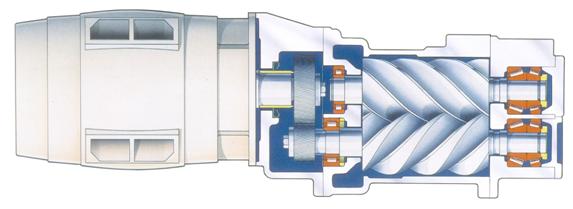

90-250KW single-stage compressor 75-350KW bipolar compression

Interview

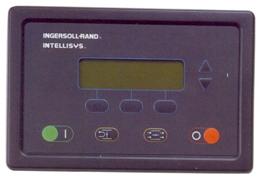

90-250KW single-stage compressor 75-350KW bipolar compression in twenty-four hours, whether you need eight hours continuous gas supply, or the intermittent use of compressed air, Intellisys intelligent controller gives you full control .

Intellisys intelligent controller to help you fully in control of compressed air displacement

In twenty-four hours , whether you need eight hours continuous gas supply , or the intermittent use of compressed air , Intellisys intelligent controller gives you full control .

All control functions at your fingertips

As long as your finger gently pressed , Intellisys intelligent controller to help you quickly and fully into the compressed air system .

Built-in multi-unit -linked controller

By Intelliys intelligent control system, you can two or four compressors joint control together . The main operating machine can be set according to the time in two or four compressors are automatically converted , so the maintenance of each machine are the same .

Easy to operate

Intellisys intelligent controller is very easy to learn and operate.

The operating parameters can be adjusted

You can quickly and easily change the operating parameters to meet the system . All their needs. If a parameter exceeds a preset limit , the control system will automatically alarm or shutdown . This saves a result of costs incurred troubleshooting and reduces downtime.

Rapid diagnostic fault

Intellisys intelligent controller monitors the operating parameters of the compressor main

Comprehensive data show

Intelligent Control System LCD display capable of displaying the main operating parameters of the compressor , so you can quickly make necessary adjustments.

The adjustable parameters work participation

With Intellisys intelligent controller, you will be able to adjust to the machine operating parameters necessary for the operation in the best condition .

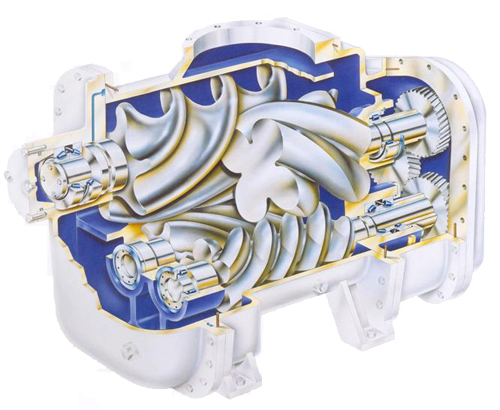

75 a two-stage compression 350kw

Energy-host

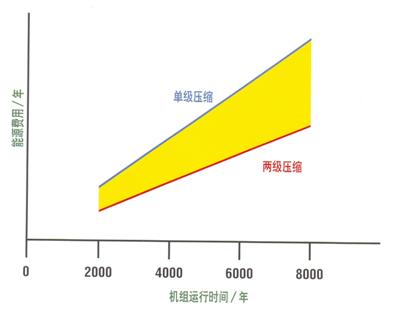

If you purchase more efficient screw compressors, please use our two air compressors. Such is the core of our compressor durable two hosts. Two compression instead of a compression can achieve up to 15% energy saving effect. After thirty rotor our finishing procedure, to ensure the accuracy of the rotor line, reliability and effectiveness.

Reduce bearing negative hormone

During each stage of compression ratio is low due to the compression, which will reduce the load on the bearing, extending the life of the host. We have chosen is the best quality bearings to ensure you are using the compressor efficient and reliable.

Coolant spray curtain

Two-stage compression is one reason for the high efficiency coolant spray curtain designs. After a level of the compressed air jet mist coolant, air cooling can achieve unexpected results. This compressed air into the secondary stage, it reduces the air temperature, greatly save the energy required for compression. And the use of coolant injection curtain design eliminates the need for an intercooler.

Design leak

SAE standard O-ring, you can completely eliminate leakage.

115F/46 ℃ temperature

Because in the design to take into account the case of high temperature environment, so our compressor to every corner of the world normal operation. The high temperature design, and can avoid the occurrence of the cooler is not operating properly downtime.

Rugged motor

SSR is equipped with especially strong in the air compressor motor. Its life is more than all the other motors, but the maintenance and repair of his motor cooling and the same.

Easy to install

SSR piping and wiring configuration of the compressor are integrated, so that all of the outside of the compressor is easy to connect.

SSR unit

To meet your compressed air system requirements, we have air-cooled and water-cooled two cooling methods for you to choose.

Factory test

To ensure that your compressor in a variety of different conditions for best performance, we have the most advanced computer mapping system, each SSR compressor factory to go through different environmental conditions to run performance tests.

Top of the exhaust

Cooling air is discharged from the top of the unit, to facilitate heat recovery, re-use.

Enclosures

A standard enclosures can minimize the generation of noise levels.

Easy service

SSR unit internal parts are arranged in perfect order, maintainability strong. Remove the panel, you can achieve the maintenance of all components.

Unique cooling

After-cooler unit is mounted on the inlet end, this will ensure that the temperature of the compressed air after cooling is higher than the ambient temperature only 15F / 8 ℃, and then through the gas post-treatment system access.

8000 hours / 2 years service life of the lubricant

Selection of super-cooling agent can reduce maintenance costs, since the unique super-cooling agent, separation performance, so that a low oil content of compressed air discharged, which also greatly reduces generation of the recycled coolant loss.

Star-delta starter

SSR advanced compressor starter allows a smooth start. As starting current is greatly reduced, thus extending the life of components improves reliability of the system.

Energy Saving Control System

Digital Control

Our unique digital control stepper motor by the intake valve system according to the requirements of the system to accurately adjust the feed rate . You simply enter the desired pressure system works , the rest of the work is to Intillisys intelligent controller to complete.

Intake control system is very reliable and do not need maintenance, because the system does not need to re- calibrate the manual pressure adjustment switch , there is no need to re- tighten the valve. Li specifically, in normal operation, do not need any manual operation.

Stepper motor control valve inlet

We give each air compressor installed not one, but three separate volume control mode : Load / unload adjustment method , a large gas production adjustment mode and automatic control adjustment mode . You just Intelliys intelligent control system set the desired control mode , the rest of the work is done by the intelligent control system .

If you want to get a comprehensive energy-saving effect , you can use the automatic control of Ingersoll Rand patented adjustment system (ACS), this system continuously monitors the entire operation of the compressor , and according to the needs of your system automatically adjusts to the load / unload control mode or large gas production adjustment method .

SSR matching items

If you need a special matching items, please contact your local sales Ingersoll Rand / dealer.

Multiple units combined control TEEC motor (90-160kw standard configuration)

Frequency control system remote control capability

Re-energized after a power failure automatic restart option water-cooled or air-cooled

Remote starter / no starter high dust intake filter

Electric high-voltage motors 6000V NEMA4 selection

Ingersoll Rand provides not only a

Compressed Air Solutions

Ingersoll Rand not only by producing more air compressors, but also through the air system to provide solutions for customers in a variety of solutions to problems and become a leader in compressed air technology. Ingersoll Rand provides customers with: rotary screw air compressor or centrifugal compressors, control systems, compressed air systems audit assessment, turnkey projects, gas, leasing and all of the services. As a result, customers know Ingersoll Rand Ingersoll Rand compressed air systems is their lifelong guardian.

Ingersoll Rand compressed air system applications over the years of experience to help you get the best solutions for compressed air

Ingersoll Rand has any kind of the world experience in application of compressed air system, we need every day for a variety of new clients to provide solutions to the new requirements. So no matter how much gas you need, how complex your environment in the field, Ingersoll Rand will provide you with the best compressed air solutions.

Ingersoll Rand's team will be relying on your firm

Ingersoll Rand has a professional team, they are responsible from product design and development to sales consulting, they have product engineers, application engineers, installation engineers and sales engineering, they will provide you with sales consulting, application engineering, installation , boot and after-sales support services, they know how to make your compressed air system to ensure optimum operating performance in the case of operating costs to a minimum. Ingersoll Rand spare parts and service team to ensure you are able to 365 days a year, 24 hours a day can have a reliable and adequate supply of compressed air.

AirCare- flexible maintenance consistent compressed air quality .

Ingersoll Rand AirCaer is provided exclusively responsive and flexible configuration maintenance agreement project , which according to customer needs to provide the appropriate service. AirCard ensures eliminate unplanned maintenance arising parking / off phenomenon , and eliminates the need to install expensive surveillance systems are subject to various fees and compressor technology by training costs .

The warranty period is extended to five years

Ingersoll Rand air compressor AirCare protocol allows you to drive or whole long warranty period to five years. So you have no worry about air compressor system .

A compressor for the purposes of any comprehensive maintenance

AirCaer also can be applied to new, overhauled or replaced key parts of the compressor . In addition , AirCaer also with

Maintenance agreement with the application to cover all parts and preventive maintenance services.

Reduce costs and improve productivity

Customers who bought the air compressor used AirCaer advantage : the periodic inspection and emergency maintenance and repair costs to avoid performance improvement obtained by the low running cost of a significant reduction in parking / Stop Time and improve productivity

AirCare to provide you with the most comprehensive set of maintenance services , including :

Provided by the IR professional technicians often block diagnosis and analysis reports using the IR -specific original spare parts and coolant is about to get a higher operating performance coolant sample analysis will be the first time to fully monitor and diagnose compressor usage a potential problem for the key parts of the vibration testing and analysis will be based on test results and trend analysis on the best time to replacement / maintenance of key components , in order to avoid losses caused serious consequences

Monitoring fortune

In AirCaer the latest addition to an option IR's Intelliguard fortune monitoring service. The 24 hours a day , week 7 monitoring system to help you in timely detection of potential problems with air compressor system and timely prevention may produce serious consequences .

Copy product links

Copy product links

Long by picture save/share

Long by picture save/share